Can flex PCBs be bent or twisted?

lex PCBs be bent or twisted

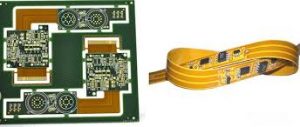

Unlike rigid PCBs that have a core with a copper surface and several layers, flex circuits have a flexible substrate made of polyester or polyimide material-films that are only 12 to 120 microns thick. Conductive material traces are then etched on the substrate and bonded with acrylic or epoxy adhesives optimized for flex circuits to prevent cracking during dynamic bending. The flexible circuit is then surrounded by a coverlay or solder mask layer that protects the thin copper from moisture and dirt. Optional stiffeners are also available that can be attached to specific areas of the flex to reduce strain, weight, and abrasion.

The smallest possible bend radius is important for a flex circuit to ensure that the copper doesn’t break. This radius is determined by the type of flex circuit: static or dynamic. Static flex circuits are designed to be bent only once, while dynamic flex circuits undergo repeated bending and twisting. When determining the minimum bend radius, consider the thickness of the PCB, the number of layers, and the flex circuit’s intended use.

To help prevent traces from breaking during bending, a designer must plan the layout of the flex circuit. For example, the bending axis should be located in the middle of the flex circuit to minimize stress and cracking at the corners of the flex pcb. Conductors should be staggered to avoid I-beaming. A plated through hole (PTH) must have at least 8 mils of clearance from the copper to prevent peeling. In addition, the shortest traces should be routed near the rigid-flex/flex interface to help reduce stresses.

Can flex PCBs be bent or twisted?

Other design considerations include the type of etching process, the layer count, and the thickness of the PCB. For instance, a thicker PCB with a larger bending radius will require a higher tolerance for flexing.

In addition, a designer must choose the type of adhesive and stiffener that will be used. There are many different types of flex adhesives available, including acrylic, epoxy, and pressure-sensitive. Stiffeners are also available in various materials, such as aluminum or FR4, to relieve strain and balance the flex circuit’s weight and heat dissipation.

It is recommended that the flex PCB be layered no more than three times, since high layers increase the thickness of the circuit. Additionally, designers should plan for a maximum of 30 degrees of bending, as more intense bends can damage the flex circuit. It is also essential to choose a flex material with the proper bend ratio, which is calculated by dividing the bend radius by the PCB’s overall thickness.