Printed Circuit Board Assembly Companies

Circuit Board Assembly Companies

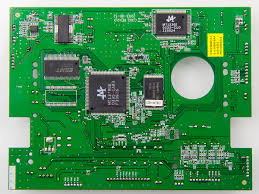

Printed circuit boards are an integral part of a number of electronic devices we use daily. The manufacturing process involves a number of intricate steps, and ensuring the quality of these pieces is paramount. A poor assembly job can lead to a product that doesn’t function properly or fails completely. To avoid these issues, many manufacturers turn to printed circuit board assembly companies for help.

As a result, it is important to choose the right assembly company for your needs. There are a number of factors to consider when choosing the best PCB assembler, from pricing and turnaround times to technical support and warehousing. Fortunately, there are a few key things to look for when evaluating potential partners.

A PCB assembler should be able to provide you with a comprehensive list of the parts that go into each project, from start to finish. This is known as a bill of materials (BOM). Whether you have an in-house team that handles this task or need to outsource it, it’s a good idea to keep track of every component that goes into the assembly process to ensure your final products are functional and reliable. A BOM will allow you to easily compare pricing and turnaround time for each project, and it’s an essential tool in the decision-making process.

Another thing to consider when selecting a printed circuit board and assembly company is the level of automation they offer. In addition to reducing production costs, the use of automated tools in the assembly process allows for greater consistency and accuracy than manual hand-assembly. This is particularly helpful for projects that require mass production of printed circuit boards, and it is a great way to ensure consistent quality while avoiding costly mistakes.

Printed Circuit Board Assembly Companies

A good PCB assembler will use the appropriate technology for each project. For example, some boards require surface mount technology, while others require through-hole technology. Some assemblers may also use automated pick and place machines to handle the placement of components on the board. These machines use mechanical or even vacuum-based movements to take a component from a feeder and put it in the correct position on the board, eliminating human error during at-scale production.

Finally, a good printed circuit board assembly company will employ a dedicated engineering team to assist clients with the design of their projects. This is especially important if the client doesn’t have an internal engineering team or has limited resources. An experienced engineer can help ensure that the design is ready for fabrication, and they can also offer suggestions to streamline the assembling and soldering processes.

In addition, a good PCB assembly company will include testing services as an integral part of the service that they offer. A jiggling component, dangling coil, or loose screw can all affect the performance of a finished product, and a thorough test will catch these problems before they make their way into the hands of customers. This is why it’s important to choose a company that offers comprehensive testing services, including visual inspections and more in-depth, component-level tests.